New Year’s Eve! I’m not much of a party animal, but I did get some trailer work done today.

I decided that I would calk the upper side of the stringers to the plywood ceiling. That way if there is some slight moisture (condensation?) it won’t get pulled into the gap, where it stays. Note that except for the top, where the roof is pretty flat, I left the lower side uncalked. After that was done the roof looked like this:

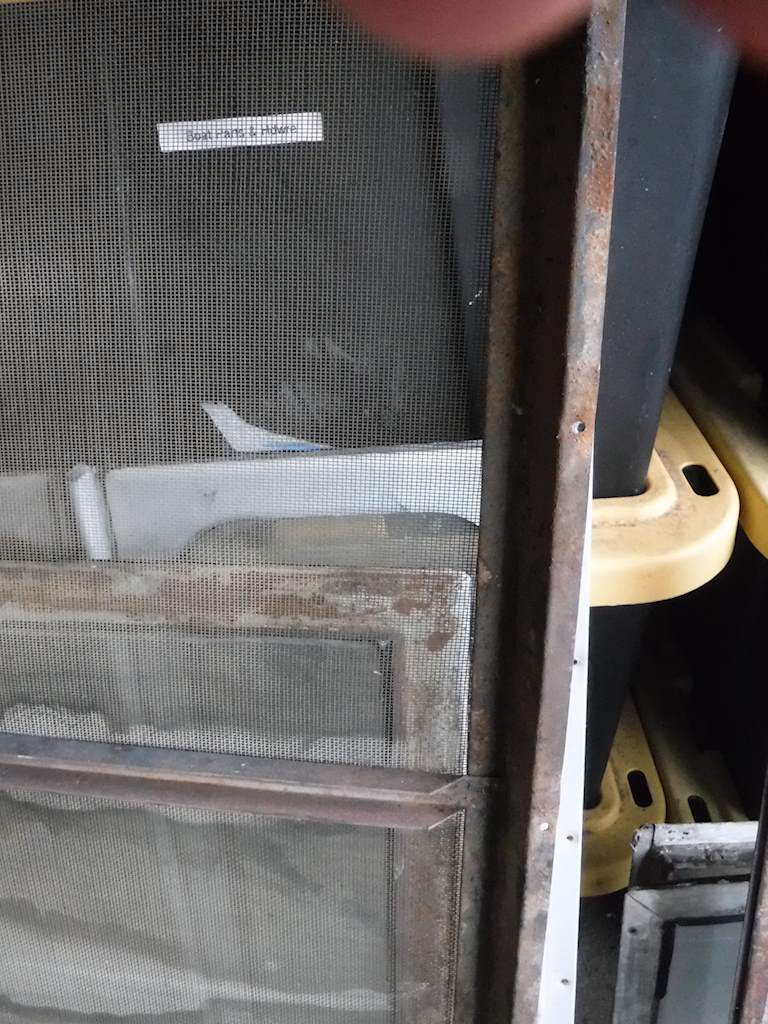

While that was curing I completed removing the roofing felt that was supposed to seal between the roof panels. At some point somebody tried some kind of roof sealant. That stuff may do something but I can’t imagine what. It’s certainly not going to seal seams in an aluminum roof. It looks like this:

I got a lot of it off, but it’s not easy and I didn’t try to get it completely clean. Even Goof-Off only loosens it a bit. Heat loosens it, but the adhesion is amazing.

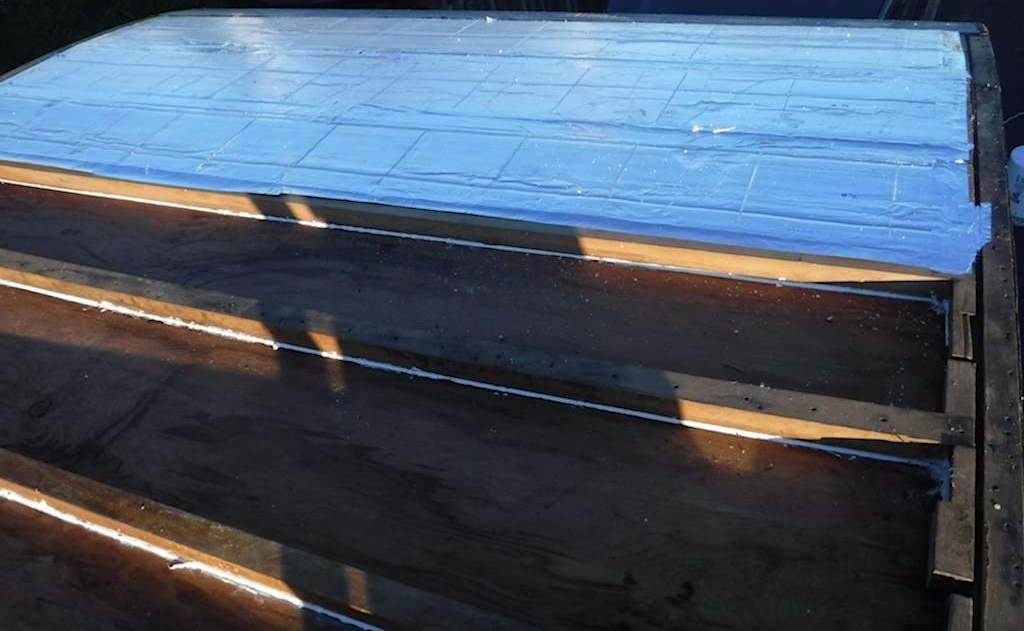

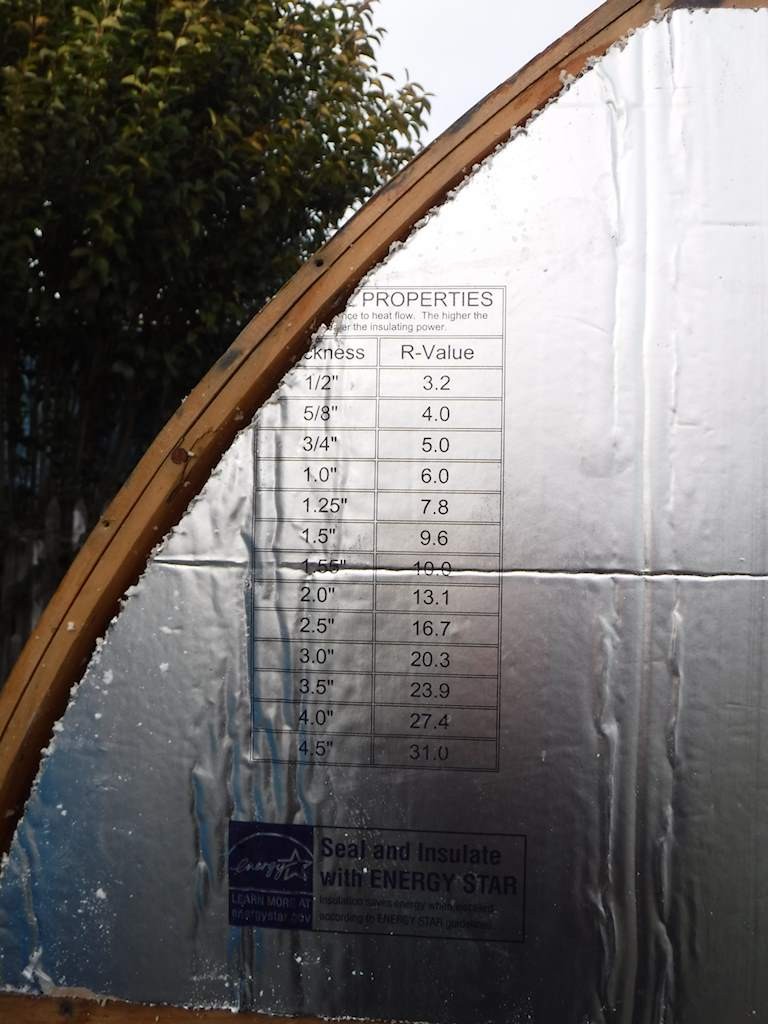

Then I started putting the polyiso insulation on. It feels good to be assembling instead of disassembling. I taped all the seams with aluminum tape, trying to get as close as possible to an airtight seal across the roof. It looks like this:

The panels across the top can just sit flat. Each gap appears to be unique, but they seem to average about a foot. On the rear just over the window there’s an sharp curve, so I slit the panel and taped over the seams as above.

The panels across the top can just sit flat. Each gap appears to be unique, but they seem to average about a foot. On the rear just over the window there’s an sharp curve, so I slit the panel and taped over the seams as above.

And here’s the first panel, on the rear, sitting in place.

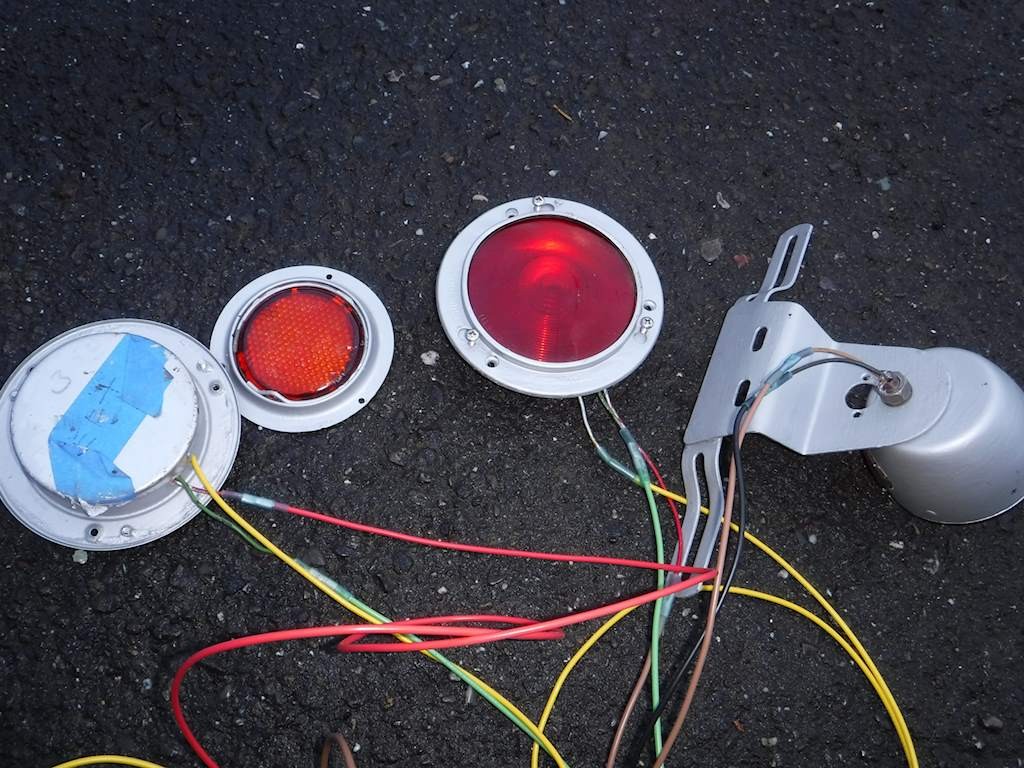

There’s a 14-2 marine wire running across from the one light to the other, under the far end. The wire you see on the left will go to the three “id” lights I’m going to add. The rules say that a trailer over 80 inches wide should have three red lights to indicate the width. I know I don’t have to meet those rules, but I think it’s wise to do so. You’ll notice the left side is all white and the right side … isn’t. That’s because I had gotten a tube of “bronze” calk by mistake. It’s not bronze, it’s dark brown. But just the color is different.

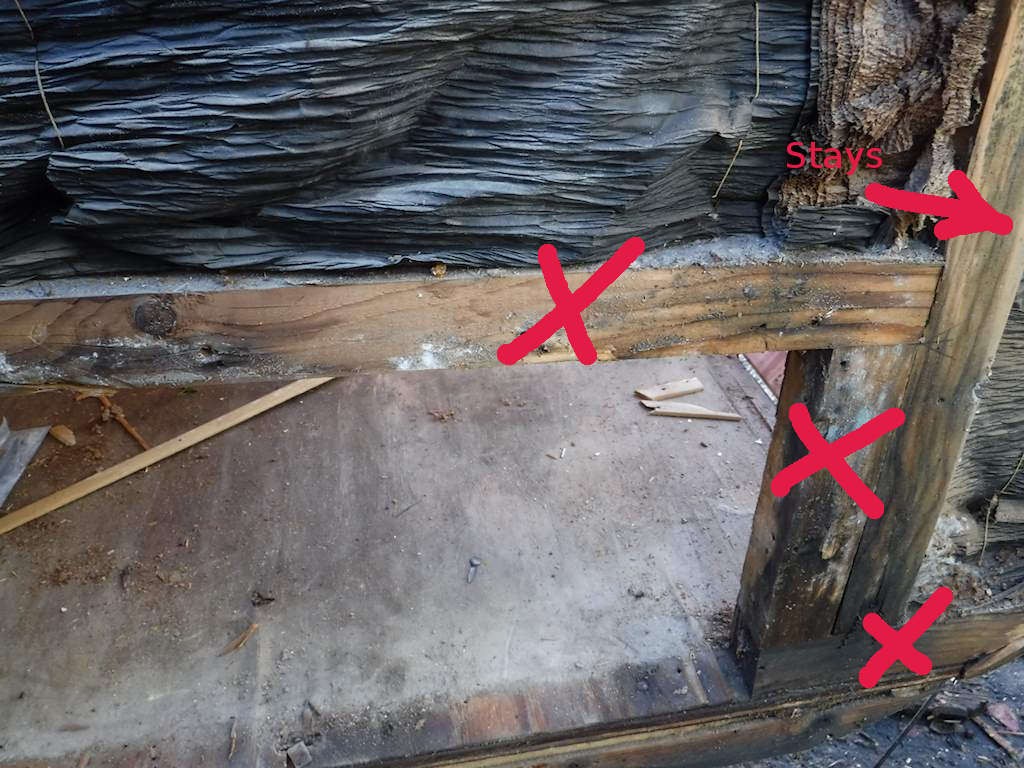

It’s not quite as extreme as this picture makes it look, but it’s real. You can see a break just to the left of the aluminum piece, which is at the door. (At the red arrow.) The plywood floor continues between the center and rear sections, but the stringers are separate and not connected. What were they thinking? It’s not that the trailer sagged- the aluminum skin proves that. It was made that way.

It’s not quite as extreme as this picture makes it look, but it’s real. You can see a break just to the left of the aluminum piece, which is at the door. (At the red arrow.) The plywood floor continues between the center and rear sections, but the stringers are separate and not connected. What were they thinking? It’s not that the trailer sagged- the aluminum skin proves that. It was made that way.