My 15 year old nephew has been visiting, so I’ve been spending time with him in preference to trailer work, but I’ve still gotten some stuff done. I got an inexpensive Harbor Freight air compressor and sand blaster. The first job was the back of the refrigerator (from 1985 but appears to work O.K.). It started out pretty rusty. The sand blaster got it to this condition:

and some high-temperature paint has it looking like this:

Then I got the final panel in on the front interior. There is a bunch of bad black stains, but I found out about oxalic acid. Apparently this is a known (to other people, not me) problem. It’s not rot at all, it’s a reaction between the rust from the iron nails and the tannins in the wood. Oxalic acid comes as a granular powder you mix with water. Just dap it on the dark spots. Normal precautions with gloves and careful handling. It started like this:

and over an hour or so with periodic sponging it on, it went to

and over an hour or so with periodic sponging it on, it went to

and eventually this:

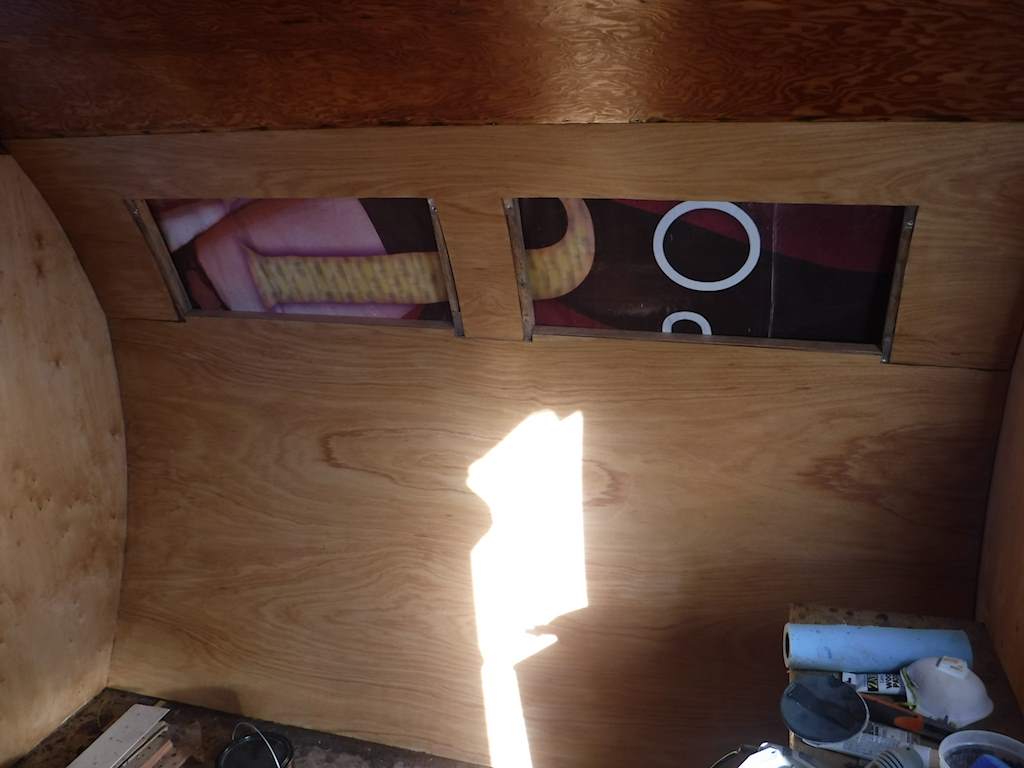

I could have done a bit more, but I kind of wanted to see how this last bit would be. Most or all of what’s left will be covered with molding. After staining and one coat of polyurethane, the front interior looks like this:

I could have done a bit more, but I kind of wanted to see how this last bit would be. Most or all of what’s left will be covered with molding. After staining and one coat of polyurethane, the front interior looks like this:

If I were starting from scratch I’d use higher quality ply than this pine stuff for the ceiling and existing walls, but with the warm stain it’s not bad. I like the many-different-woods look and will be expanding that approach.

The next step is a big one. I need to separate the house from the frame so I can de-rust and paint the frame and replace the floor. More to come.